ERP system development sets the stage for this enthralling narrative, offering readers a glimpse into a story that is rich in detail with casual formal language style and brimming with originality from the outset.

This comprehensive exploration delves into the core motivations, intricate design processes, technological architectures, data modeling, agile methodologies, user experience considerations, data migration challenges, and advanced functionalities that define modern ERP system development. It aims to provide a thorough understanding of how businesses can leverage integrated software to achieve expansion and operational excellence.

Unraveling the Fundamental Motivations Behind Adopting an Enterprise Resource Planning System for Business Expansion.

As businesses grow, the complexity of managing their operations increases exponentially. What starts as a manageable set of processes can quickly become a tangled web of disparate systems and manual workarounds. This is where the strategic adoption of an Enterprise Resource Planning (ERP) system emerges not just as a technological upgrade, but as a fundamental enabler of sustainable business expansion.

The core business drivers that propel organizations toward investing in sophisticated software for integrated management are multifaceted, touching upon efficiency, visibility, scalability, and ultimately, profitability. Without a unified platform, businesses risk encountering bottlenecks, data silos, and a lack of real-time insights, all of which can stifle growth and hinder competitive agility. The decision to implement an ERP is therefore a proactive step towards creating a more robust, responsive, and future-ready organization.The journey of business expansion is often fraught with challenges that can be significantly mitigated by a well-implemented ERP system.

At its heart, the adoption of such a system is driven by the need for greater control and understanding across all business functions. Organizations realize that fragmented data leads to fragmented decision-making. For instance, a sales team might not have real-time visibility into inventory levels, leading to overselling and customer dissatisfaction. Similarly, the finance department might struggle to reconcile expenses with project progress if project management data is not integrated.

These inefficiencies not only cost time and money but also erode customer trust and employee morale. An ERP system acts as a central nervous system, connecting departments like finance, human resources, manufacturing, supply chain, services, procurement, and more. This integration fosters a single source of truth, empowering every stakeholder with accurate, up-to-date information. The ability to streamline processes, automate repetitive tasks, and gain a holistic view of the business are paramount motivations for embracing ERP, especially when the scale of operations demands a more sophisticated approach to management.

Core Business Drivers for ERP Adoption

The decision to invest in an Enterprise Resource Planning (ERP) system is rarely a superficial one; it is typically underpinned by a set of critical business imperatives that become increasingly pronounced as a company expands. These drivers are rooted in the need to overcome the limitations of legacy systems and manual processes, which become unsustainable at scale.

- Enhanced Operational Efficiency and Automation: As businesses grow, manual data entry, redundant tasks, and disconnected workflows become significant drains on resources and time. ERP systems automate many of these processes, from order processing and inventory management to payroll and financial reporting. This automation reduces the likelihood of human error, speeds up transaction cycles, and frees up employees to focus on more strategic initiatives.

For example, in a manufacturing setting, an ERP can automatically trigger raw material orders when inventory levels fall below a predefined threshold, preventing production delays.

- Improved Data Accuracy and Visibility: In a growing organization, maintaining consistent and accurate data across various departments is a monumental task. Disparate systems often lead to conflicting information, making it difficult to get a clear picture of the business’s performance. ERP systems provide a centralized database, ensuring that all data is entered once and is accessible to all authorized users. This single source of truth leads to more reliable reporting, better decision-making, and a reduced risk of costly errors stemming from inaccurate information.

- Scalability and Future-Proofing: Expansion inherently means an increase in transaction volumes, customer base, and operational complexity. Legacy systems that were adequate for a smaller operation often buckle under this increased pressure. An ERP system is designed to scale with the business, accommodating growth without requiring a complete overhaul of the IT infrastructure. This scalability ensures that the business can continue to expand without being hindered by its technological backbone.

- Streamlined Compliance and Reporting: As businesses grow and operate in more regulated environments, adhering to compliance standards and generating accurate financial and operational reports becomes increasingly critical. ERP systems often have built-in features that support regulatory compliance, such as audit trails, segregation of duties, and standardized reporting formats. This simplifies the process of meeting legal and industry-specific requirements.

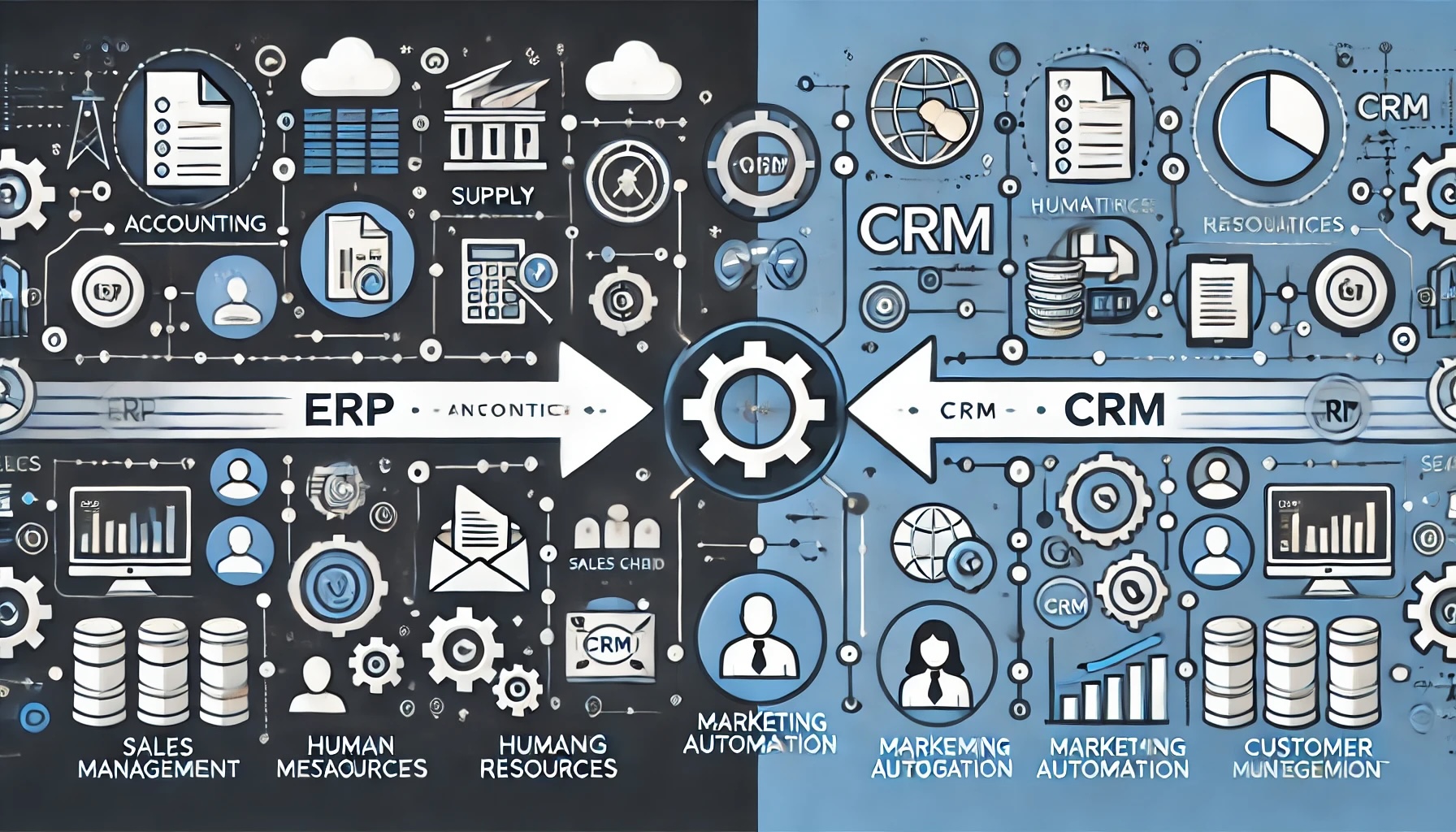

- Better Customer Relationship Management: With increased business comes a larger customer base, and managing these relationships effectively is crucial. While not always the primary driver, ERP systems often integrate with or include CRM functionalities, providing a unified view of customer interactions, order history, and service requests. This allows for more personalized service and proactive issue resolution.

Strategic Advantages of Centralizing Operational Data and Workflows

The strategic advantages gained by centralizing operational data and workflows through an ERP system are profound and directly contribute to a company’s ability to expand effectively. This centralization transforms a collection of independent operational units into a cohesive, high-performing entity.

- Enhanced Decision-Making Capabilities: When data is siloed, decision-makers often operate with incomplete or outdated information. Centralizing data in an ERP system provides a unified, real-time view of all business operations. This allows for more informed and timely decisions across all levels of the organization. For instance, a marketing campaign can be better targeted if sales data and customer feedback are readily accessible.

Similarly, financial projections can be more accurate when they are based on integrated sales, procurement, and production data.

- Improved Cross-Departmental Collaboration: A common challenge in growing businesses is the lack of seamless communication and collaboration between departments. Centralized workflows within an ERP system break down these barriers. When everyone is working from the same data and using the same processes, handoffs between departments become smoother, reducing delays and misunderstandings. For example, the sales team can immediately see when an order has been approved and passed to production, and the production team can access all necessary order details without needing to request them separately.

- Greater Agility and Responsiveness: In today’s dynamic market, businesses need to be able to adapt quickly to changing conditions. A centralized ERP system provides the agility to do so. By having a clear overview of all operations, management can identify potential issues or opportunities faster and implement changes more efficiently. For example, if a supply chain disruption occurs, the impact on production and delivery schedules can be quickly assessed, allowing for proactive adjustments.

- Standardization of Business Processes: As a business expands, maintaining consistency in how tasks are performed becomes essential for quality and efficiency. ERP systems enforce standardized processes across the organization. This means that whether an order is placed in one region or another, or by different employees, it follows the same established procedure, leading to predictable outcomes and reduced variability. This standardization is particularly crucial in industries with strict quality control requirements.

- Enhanced Supply Chain Management: Centralizing data allows for a more integrated and efficient supply chain. Real-time visibility into inventory levels, demand forecasts, and supplier performance enables better procurement decisions, optimized stock levels, and reduced lead times. This can lead to significant cost savings and improved customer satisfaction through reliable delivery.

Impact on Operational Efficiency and Resource Allocation

The implementation of an Enterprise Resource Planning (ERP) system directly impacts operational efficiency and resource allocation by providing the tools and insights necessary to optimize every facet of the business. This impact is not theoretical; it translates into tangible improvements in productivity, cost reduction, and strategic deployment of assets.

- Streamlined Workflows and Reduced Bottlenecks: Before ERP, operational workflows often involved manual data transfer between departments, leading to delays and errors. An ERP system integrates these processes, creating a seamless flow of information. For instance, a sales order can automatically trigger inventory checks, production planning, and shipping notifications without manual intervention. This significantly reduces lead times and eliminates common bottlenecks that impede efficiency.

- Optimized Inventory Management: Inefficient inventory management is a major drain on resources, leading to excess stock that ties up capital or stockouts that result in lost sales. ERP systems provide real-time visibility into inventory levels, demand patterns, and lead times. This allows businesses to implement just-in-time inventory strategies, forecast demand more accurately, and optimize stock levels, thereby reducing holding costs and minimizing the risk of stockouts.

- Improved Financial Management and Control: ERP systems centralize financial data, providing a comprehensive view of the company’s financial health. This includes real-time tracking of revenues, expenses, accounts payable and receivable, and budgeting. The automation of financial processes, such as invoicing and payroll, reduces manual effort and minimizes errors. Furthermore, robust reporting capabilities allow for better financial analysis, enabling more strategic resource allocation and cost control.

- Enhanced Human Resource Management: Beyond just payroll, ERP systems can manage various HR functions, including employee data, recruitment, training, and performance management. By centralizing this information, HR departments can operate more efficiently, and managers gain better insights into workforce capabilities and needs. This allows for more effective resource allocation of human capital, ensuring the right people are in the right roles and that training investments are aligned with business objectives.

- Better Utilization of Assets and Equipment: For businesses with physical assets or machinery, ERP systems can play a crucial role in optimizing their utilization. Through integrated production planning and maintenance scheduling modules, businesses can ensure that equipment is used to its full capacity and that maintenance is performed proactively, minimizing downtime. This leads to increased productivity and a longer lifespan for valuable assets, thereby improving resource allocation and return on investment.

“An ERP system transforms operational data from a scattered liability into a unified asset, enabling precise resource allocation and driving efficiency gains that are critical for scaling.”

Charting the intricate journey of designing and building a custom enterprise resource planning solution from the ground up.

Building a custom Enterprise Resource Planning (ERP) system is a significant undertaking, akin to constructing a new headquarters for your business operations. It’s not a plug-and-play solution; rather, it’s a carefully orchestrated process of understanding, designing, and implementing a system tailored precisely to your unique operational DNA. This journey requires a strategic, phased approach to ensure that the final product not only meets current needs but also scales effectively with future growth.

The investment in time, resources, and expertise is substantial, but the rewards of a perfectly aligned ERP can be transformative, driving efficiency, improving decision-making, and fostering a competitive edge.This section delves into the detailed steps involved in bringing a bespoke ERP system to life, from its initial conception through to its final deployment. We will explore a structured, phased methodology that breaks down this complex project into manageable stages.

Furthermore, we will identify the core modules and functionalities that form the backbone of any robust ERP, considering the diverse requirements of modern businesses. Finally, we will Artikel a systematic framework for capturing and translating intricate business needs into precise technical specifications that guide the development process.

Phased Approach to Bespoke ERP Development

Developing a custom ERP system from scratch is a marathon, not a sprint. A well-defined phased approach is crucial for managing complexity, mitigating risks, and ensuring that each stage builds upon the last, leading to a robust and functional system. This structured methodology allows for iterative feedback, adaptation to evolving business needs, and efficient resource allocation. Each phase has distinct objectives and deliverables, contributing to the overall success of the project.The initial phase, Discovery and Planning, is foundational.

It involves a deep dive into the business’s current state, identifying pain points, understanding workflows, and defining high-level objectives for the ERP. This includes stakeholder interviews, process mapping, and competitive analysis. The outcome is a detailed project charter, a feasibility study, and a preliminary scope document. This phase sets the strategic direction and ensures buy-in from all key parties.Following this is the Requirements Gathering and Analysis phase.

This is where the detailed “what” of the system is defined. It involves translating business needs into functional and non-functional requirements. Techniques such as workshops, surveys, and use-case development are employed. The output is a comprehensive Software Requirements Specification (SRS) document that serves as the blueprint for the entire development effort. Accuracy and completeness here are paramount to avoid costly rework later.The Design and Architecture phase translates the SRS into a technical blueprint.

This involves defining the system’s architecture, database design, user interface (UI) and user experience (UX) design, and integration strategies with existing systems. Prototyping and wireframing are often used to visualize the system and gather early feedback on usability. A well-defined architecture ensures scalability, maintainability, and security.Next comes the Development and Coding phase. This is the core construction period where developers build the system based on the design specifications.

Get the entire information you require about best accounting software for inventory on this page.

It typically follows an agile methodology, with iterative development cycles (sprints) and continuous integration. Regular testing and code reviews are conducted to maintain quality and adherence to standards.The Testing and Quality Assurance phase is critical for ensuring the system functions as intended and meets all specified requirements. This includes unit testing, integration testing, system testing, user acceptance testing (UAT), and performance testing.

Any bugs or defects identified are logged, prioritized, and fixed by the development team. UAT is particularly important as it involves end-users validating the system against their daily operational needs.The Deployment and Implementation phase involves rolling out the tested system into the production environment. This can be done in phases or as a big bang approach, depending on the business’s risk tolerance and operational constraints.

Data migration from legacy systems, user training, and go-live support are key components of this phase.Finally, the Post-Implementation Support and Optimization phase ensures the system continues to perform optimally. This includes ongoing maintenance, bug fixes, performance monitoring, and future enhancements based on user feedback and evolving business needs. Regular system audits and updates are essential for long-term success.

Essential Modules and Functionalities of a Comprehensive ERP System

A truly comprehensive ERP system acts as the central nervous system for an organization, integrating disparate business functions into a cohesive and efficient whole. The modular nature of ERP allows businesses to select and implement functionalities that are most relevant to their operations, while still benefiting from the interconnectedness of the data. The goal is to streamline processes, improve data accuracy, enhance visibility, and enable better decision-making across the entire enterprise.At its core, an ERP system typically encompasses several key modules, each addressing a specific business domain.

The Financial Management module is often considered the most critical. It handles all aspects of accounting, including general ledger, accounts payable, accounts receivable, budgeting, fixed asset management, and financial reporting. This module ensures accurate financial data, compliance with regulations, and provides insights into the company’s financial health.The Human Resources Management (HRM) module manages the entire employee lifecycle. This includes payroll processing, benefits administration, time and attendance tracking, recruitment, onboarding, performance management, and employee data management.

A robust HRM module helps in managing the workforce efficiently, ensuring compliance with labor laws, and fostering employee satisfaction.The Supply Chain Management (SCM) module is vital for businesses involved in manufacturing, distribution, or retail. It covers procurement, inventory management, warehousing, logistics, order fulfillment, and supplier relationship management. This module optimizes the flow of goods and information from raw materials to the end customer, reducing costs and improving delivery times.The Customer Relationship Management (CRM) module focuses on managing interactions with current and potential customers.

It includes sales force automation, marketing automation, customer service and support, and contact management. A well-implemented CRM module helps in improving customer satisfaction, increasing sales, and building stronger customer loyalty.For manufacturing businesses, the Manufacturing Operations Management module is indispensable. This includes production planning and scheduling, material requirements planning (MRP), shop floor control, quality management, and bill of materials (BOM) management. It ensures efficient production processes, optimal resource utilization, and consistent product quality.The Project Management module is crucial for organizations that undertake complex projects.

It facilitates project planning, resource allocation, task management, budget tracking, and progress monitoring. This module helps in delivering projects on time and within budget, improving project profitability and client satisfaction.Furthermore, a comprehensive ERP system often includes Business Intelligence (BI) and Analytics capabilities. This module provides tools for data analysis, reporting, and dashboard creation, allowing users to gain actionable insights from the vast amounts of data generated by other modules.

This empowers data-driven decision-making and strategic planning.Finally, Inventory Management as a standalone or integrated module is crucial for controlling stock levels, managing warehouse operations, tracking stock movements, and optimizing inventory turnover. This module directly impacts cost of goods sold, customer order fulfillment rates, and overall operational efficiency.

Framework for Gathering and Translating Business Requirements into Technical Specifications

The successful development of a custom ERP system hinges on the accurate and comprehensive translation of complex business requirements into actionable technical specifications. This process bridges the gap between what the business needs to achieve and how the system will be built to enable it. A structured framework ensures that all critical aspects are captured, understood, and documented in a way that developers can clearly interpret and implement.The initial step in this framework is Stakeholder Identification and Engagement.

It’s vital to identify all individuals and groups who will be impacted by or have influence over the ERP system. This includes end-users from various departments, managers, IT personnel, and executive leadership. Engaging them early and consistently through workshops, interviews, and surveys is key to understanding their perspectives and gathering a holistic view of needs.Following this, Business Process Analysis and Mapping is performed.

This involves meticulously documenting current business processes, identifying inefficiencies, bottlenecks, and areas for improvement. Visual tools like flowcharts and process diagrams are invaluable here. This analysis helps in understanding not just what users do, but why they do it, and how the ERP can streamline these activities.The core of the framework lies in Requirements Elicitation and Documentation. This phase involves actively drawing out detailed requirements.

These requirements are typically categorized into:* Functional Requirements: These describe what the systemshould do*. For example, “The system shall allow users to generate a monthly sales report filtered by region and product category.”

-

Non-Functional Requirements

These describe

- how well* the system should perform. Examples include performance (e.g., “System response time for critical queries must be under 3 seconds”), security (e.g., “User access must be role-based and encrypted”), usability (e.g., “The user interface must be intuitive and require minimal training”), and reliability (e.g., “The system must have 99.9% uptime”).

These requirements are then documented in a formal Software Requirements Specification (SRS) document. The SRS should be clear, concise, unambiguous, and verifiable. It serves as the single source of truth for the development team.Next, Requirement Prioritization is undertaken. Not all requirements are of equal importance or urgency. Using techniques like MoSCoW (Must have, Should have, Could have, Won’t have) or Weighted Shortest Job First (WSJF), stakeholders and the development team collaboratively prioritize requirements.

This ensures that the most critical functionalities are addressed first, especially in an agile development context.The crucial step of Translating Requirements into Technical Specifications involves converting the documented requirements into detailed technical designs. This includes:* Data Modeling: Defining the database schema, tables, relationships, and data types.

User Interface (UI) and User Experience (UX) Design

Creating wireframes, mockups, and prototypes to define the look, feel, and user flow of the system.

System Architecture Design

Outlining the overall structure of the system, including its components, modules, and how they interact.

Integration Specifications

Detailing how the new ERP system will interface with existing software and hardware.

API Design

If applicable, defining the Application Programming Interfaces for external system interaction.This translation is often facilitated by Use Case Diagrams and User Stories. Use cases describe interactions between users and the system to achieve specific goals, while user stories provide a concise description of a feature from an end-user’s perspective, typically in the format: “As a [type of user], I want [an action] so that [a benefit].”Finally, Requirement Validation and Verification ensures that the translated specifications accurately reflect the business needs and are technically feasible.

This involves design reviews, walkthroughs with stakeholders and the development team, and ensuring that each technical specification can be traced back to a business requirement. This iterative process of validation and refinement is key to building an ERP system that truly serves its intended purpose.

Exploring the diverse technological architectures that underpin modern enterprise resource planning system development.

The landscape of Enterprise Resource Planning (ERP) system development is continually shaped by advancements in technology, leading to a variety of architectural approaches. Understanding these architectures is crucial for businesses aiming to select or build a solution that aligns with their operational needs, scalability requirements, and long-term strategic goals. This exploration delves into the foundational technological frameworks that empower modern ERP systems, examining their implications for deployment, flexibility, and integration.The choice of technological architecture significantly influences an ERP system’s cost, performance, security, and adaptability.

As businesses evolve and the digital environment becomes more dynamic, the underlying architecture must be robust enough to support these changes. This section will dissect key architectural paradigms, highlighting their strengths and weaknesses to provide a comprehensive overview for informed decision-making.

Cloud-Based Versus On-Premise Deployment Models for Enterprise Resource Planning Software

The decision between a cloud-based and an on-premise deployment model is one of the most fundamental choices when adopting or developing an ERP system. Each model presents a distinct set of advantages and disadvantages that directly impact a company’s operational costs, IT infrastructure, security posture, and flexibility. Understanding these differences is paramount for aligning the ERP solution with business objectives.On-premise ERP systems involve hosting the software and all associated data on a company’s own servers and IT infrastructure.

This offers a high degree of control over data security, customization, and system access. Businesses that handle highly sensitive data or operate in heavily regulated industries might find the complete control offered by on-premise solutions appealing. Furthermore, once the initial investment in hardware and software licenses is made, ongoing costs are primarily related to maintenance, support, and IT staff. However, the upfront capital expenditure can be substantial, and the responsibility for managing hardware, software updates, patches, and security falls entirely on the organization.

Scalability can also be a challenge; expanding capacity often requires significant hardware upgrades and lead times. Disaster recovery and business continuity planning are also complex and costly to implement independently.Cloud-based ERP, often delivered as Software-as-a-Service (SaaS), involves hosting the ERP system on the vendor’s servers and accessing it over the internet. This model shifts the capital expenditure to an operational expense, typically through subscription fees.

The primary benefits include lower upfront costs, faster deployment, and automatic updates and maintenance handled by the vendor. Scalability is a significant advantage, as businesses can easily adjust their subscription to accommodate growth or seasonal fluctuations. Access from anywhere with an internet connection enhances mobility and collaboration. However, reliance on the vendor for security and data privacy is a key consideration.

While reputable cloud providers invest heavily in security, companies relinquish direct control over their data. Customization options might be more limited compared to on-premise solutions, and a stable internet connection is essential for uninterrupted access. Vendor lock-in and potential data egress fees are also factors to weigh. For example, a rapidly growing e-commerce startup might find the immediate scalability and lower initial investment of a cloud ERP ideal, whereas a large financial institution with stringent data sovereignty requirements might opt for the control of an on-premise solution.

Significance of Microservices Architecture in Fostering Flexibility and Scalability within Enterprise Resource Planning Development

The evolution of ERP systems from monolithic structures to more modular designs has been significantly driven by the adoption of microservices architecture. This architectural style decomposes an application into a collection of small, independent, and loosely coupled services, each responsible for a specific business capability. This fundamental shift offers unprecedented flexibility and scalability, addressing many limitations of traditional ERP development.In a microservices-based ERP, each module, such as inventory management, financial accounting, human resources, or customer relationship management, can be developed, deployed, and scaled independently.

This means that if the demand for a specific function, like order processing during a peak sales season, increases dramatically, only that particular service needs to be scaled up, rather than the entire ERP system. This granular scalability is far more efficient and cost-effective than scaling a monolithic application, where resources would be over-allocated to less utilized modules. Furthermore, teams can work on and deploy individual services without impacting other parts of the system, accelerating development cycles and enabling faster innovation.

This is a stark contrast to monolithic architectures, where a small change in one module could necessitate extensive testing and redeployment of the entire application, leading to longer release cycles and increased risk.The flexibility afforded by microservices also extends to technology choices. Different services can be built using different programming languages, databases, and frameworks best suited for their specific tasks.

For instance, a real-time analytics service might leverage a high-performance in-memory database, while a reporting service might use a more traditional relational database. This polyglot persistence and programming approach allows developers to select the optimal tools for each job, leading to more efficient and robust solutions. For businesses, this translates to a more adaptable ERP system that can more easily integrate new technologies or replace outdated components without a complete system overhaul.

For example, if a company decides to adopt a new AI-powered forecasting tool, a microservices architecture allows for the development of a dedicated service for this functionality, which can then be seamlessly integrated with existing ERP modules, rather than requiring a massive rewrite of the entire system. This modularity also simplifies maintenance and troubleshooting, as issues are often isolated to specific services, making them easier to identify and resolve.

Critical Integration Points and Middleware Strategies for Seamless Interoperability with Existing Business Applications, Erp system development

For an Enterprise Resource Planning (ERP) system to truly deliver on its promise of unifying business operations, it must seamlessly interact with the myriad of existing applications that a company already utilizes. These integration points are critical junvous, and the strategies employed to manage them dictate the flow of information, the efficiency of processes, and the overall effectiveness of the ERP implementation.

Without robust interoperability, an ERP system can become an isolated data silo, hindering rather than helping business expansion.Key integration points typically revolve around core business functions and data. For instance, an ERP system needs to connect with customer relationship management (CRM) systems to synchronize customer data, sales orders, and service requests. E-commerce platforms require integration to push product catalogs, receive orders, and manage inventory levels in real-time.

Manufacturing execution systems (MES) need to interface with the ERP for production planning, material requirements, and cost tracking. Financial systems, such as specialized accounting software or banking platforms, also demand close integration for transaction processing, reconciliation, and reporting. Furthermore, supply chain management (SCM) tools, warehouse management systems (WMS), and even human capital management (HCM) solutions represent common areas where ERP integration is essential.Middleware strategies are the backbone of achieving this seamless interoperability.

These strategies provide the bridge between disparate applications, translating data formats, orchestrating workflows, and managing communication protocols. One common approach is the use of Enterprise Service Buses (ESBs). An ESB acts as a central hub, allowing applications to communicate with each other without direct point-to-point connections. This simplifies management and reduces complexity as new applications are added. For example, instead of creating individual connections between an ERP, a CRM, and an e-commerce platform, each application connects to the ESB, which then routes messages and transforms data as needed.

Another increasingly popular strategy is an API-led connectivity approach, which leverages Application Programming Interfaces (APIs) to enable applications to interact in a standardized way. This promotes a more agile and flexible integration environment. For instance, a well-defined set of APIs for the ERP system can allow external applications, such as a mobile sales app or a partner portal, to access and update ERP data in a controlled and secure manner.

Event-driven architectures, where applications communicate by publishing and subscribing to events, are also crucial for real-time data synchronization. This ensures that when an event occurs in one system (e.g., a new order is placed), other connected systems are immediately notified and can react accordingly. The selection of the right middleware and integration strategy depends heavily on the complexity of the existing IT landscape, the volume and velocity of data, and the desired level of real-time interaction.

Demonstrating the critical role of data modeling and database design in the creation of robust enterprise resource planning systems.: Erp System Development

At the heart of any successful Enterprise Resource Planning (ERP) system lies a well-structured and meticulously designed database. This is where all the operational data, from customer interactions to financial transactions and inventory levels, is stored, managed, and made accessible. Without a solid foundation in data modeling and database design, an ERP system would be akin to a building with a weak foundation – prone to collapse under the weight of its own complexity and operational demands.

The principles of relational database design are paramount in ensuring data integrity, efficiency, and scalability, which are non-negotiable for systems that underpin an entire business.The process of developing a robust ERP solution is intrinsically linked to how its data is conceptualized, organized, and stored. Data modeling acts as the blueprint, defining the entities that represent business concepts and the relationships between them.

This blueprint then guides the database design, translating the conceptual model into a physical structure that can efficiently store and retrieve information. This intricate dance between conceptualization and physical implementation is what allows ERP systems to provide a unified view of business operations, enabling informed decision-making and streamlined processes across departments. The investment in thorough data modeling and database design upfront pays significant dividends in system performance, maintainability, and the ability to adapt to future business needs.

Principles of Relational Database Design for Enterprise Resource Planning

Relational database design is the bedrock upon which modern ERP systems are built, providing a structured and logical approach to managing complex business data. The core principles ensure data consistency, minimize redundancy, and facilitate efficient data retrieval, all of which are critical for the high-volume, transactional nature of ERP operations. Understanding these principles is essential for anyone involved in the development or implementation of an ERP solution.The primary goal of relational database design is to organize data into tables, where each table represents an entity, and each row within a table represents an instance of that entity.

Columns within a table represent the attributes of that entity. The relationships between these tables are established through keys, most notably primary keys (which uniquely identify a record within a table) and foreign keys (which link records in one table to records in another). This structure inherently enforces data integrity. For instance, if a product is associated with a specific supplier, a foreign key in the product table referencing the supplier table ensures that only valid supplier IDs can be assigned.Normalization is a key process in relational database design, aimed at reducing data redundancy and improving data integrity.

It involves organizing columns and tables in a database so that data is stored in the most logical way. The process typically moves through several normal forms (1NF, 2NF, 3NF, and sometimes higher), each with progressively stricter rules. For ERP systems, achieving at least Third Normal Form (3NF) is generally considered best practice. This means that non-key attributes are dependent only on the primary key, and not on other non-key attributes.

This prevents anomalies that can occur during data insertion, update, or deletion. For example, if customer addresses were stored directly in the order table, updating an address would require modifying multiple order records, increasing the risk of inconsistencies. By normalizing, customer information is stored in a separate customer table, linked to orders via a customer ID.The efficiency of an ERP system is heavily reliant on effective indexing strategies.

Indexes are special lookup tables that the database search engine can use to speed up data retrieval operations. For ERP systems, which often involve complex queries across multiple tables, proper indexing of frequently queried columns, especially foreign keys, is crucial for maintaining acceptable performance levels. This includes considering composite indexes for queries that involve multiple criteria.

“Data integrity is not a feature; it is a fundamental requirement for any business-critical system like ERP.”

The following table illustrates some key aspects of relational database design principles applied to ERP:

| Principle | Description | ERP Application Example |

|---|---|---|

| Entity Integrity | Each table must have a primary key, and the primary key value cannot be NULL. | Each ‘Customer’ record must have a unique ‘CustomerID’ that is never empty. |

| Referential Integrity | Foreign key values must match a primary key value in the referenced table or be NULL. | An ‘OrderID’ in the ‘OrderItems’ table must correspond to an existing ‘OrderID’ in the ‘Orders’ table. |

| Data Redundancy Minimization | Storing the same data multiple times should be avoided. | Customer contact details are stored once in the ‘Customers’ table, not repeated for every order. |

| Normalization | Organizing data to reduce redundancy and improve data integrity, typically up to 3NF. | Separating product details, pricing, and inventory levels into distinct, related tables. |

Creating an Entity-Relationship Diagram for Core Enterprise Resource Planning Modules

The Entity-Relationship Diagram (ERD) is an indispensable tool in the initial stages of ERP development, serving as a visual blueprint that maps out the entities within the system and the relationships that bind them. It provides a high-level, conceptual understanding of the data landscape, facilitating communication between business stakeholders and technical teams, and guiding the subsequent database design. For ERP systems, which integrate diverse business functions, a well-crafted ERD is crucial for ensuring that all critical data points and their interdependencies are identified and correctly represented.The process of creating an ERD for core ERP modules typically begins with identifying the key business entities.

For instance, in a typical sales and inventory management context, core entities might include ‘Customers’, ‘Products’, ‘Sales Orders’, ‘Order Items’, ‘Suppliers’, and ‘Inventory’. Each entity is represented by a rectangular box in the diagram. Within these boxes, the attributes of the entity are listed. For example, the ‘Customer’ entity might have attributes like ‘CustomerID’ (primary key), ‘FirstName’, ‘LastName’, ‘Email’, and ‘ShippingAddress’.Once entities and their attributes are defined, the next crucial step is to identify and define the relationships between them.

Relationships are typically depicted as lines connecting the entity boxes, with symbols indicating the cardinality and optionality of the relationship. Cardinality describes the number of instances of one entity that can be related to the number of instances of another entity. Common types include:

- One-to-One (1:1): Each instance of Entity A relates to exactly one instance of Entity B, and vice-versa. (e.g., A ‘User’ might have one ‘UserProfile’).

- One-to-Many (1:N): One instance of Entity A can relate to many instances of Entity B, but each instance of Entity B relates to only one instance of Entity A. (e.g., One ‘Customer’ can place many ‘Sales Orders’).

- Many-to-Many (M:N): One instance of Entity A can relate to many instances of Entity B, and vice-versa. (e.g., Many ‘Products’ can be part of many ‘Sales Orders’).

For many-to-many relationships, an intermediate or “junction” table is typically introduced in the physical database design to break it down into two one-to-many relationships. For example, a direct M:N relationship between ‘Products’ and ‘Sales Orders’ would be resolved by an ‘Order Items’ table, which links specific products to specific orders and can also store quantity and price information for that particular line item.Optionality, often denoted by symbols like a circle for optional and a crow’s foot for mandatory, indicates whether a relationship is required.

For example, a ‘Sales Order’ must have at least one ‘Order Item’ (mandatory), but a ‘Product’ might exist in the catalog without currently being part of any ‘Sales Order’ (optional).Let’s consider the ERD for a simplified order processing flow:* Customers: Represents individuals or companies that purchase products. Attributes: CustomerID (PK), Name, Email, Phone, Address.

Products

Represents items available for sale. Attributes: ProductID (PK), ProductName, Description, UnitPrice.

Sales Orders

Represents a customer’s request for products. Attributes: OrderID (PK), CustomerID (FK), OrderDate, TotalAmount, Status.

Order Items

A junction table linking Sales Orders and Products, detailing specific items within an order. Attributes: OrderItemID (PK), OrderID (FK), ProductID (FK), Quantity, LineItemPrice.The relationships would be:

‘Customers’ to ‘Sales Orders’

One-to-Many (A customer can have many orders).

‘Sales Orders’ to ‘Order Items’

One-to-Many (An order can have many items).

‘Products’ to ‘Order Items’

One-to-Many (A product can appear in many order items).

The relationship between ‘Sales Orders’ and ‘Products’ is effectively Many-to-Many, resolved through the ‘Order Items’ table.

This ERD forms the basis for the database schema, ensuring that the logical structure of the data accurately reflects business requirements and facilitates efficient data management within the ERP system.

Hypothetical Data Schema Illustrating Relationships Between Key Entities

Building upon the conceptual model derived from an ERD, a hypothetical data schema can be constructed to illustrate the practical implementation of relationships between core ERP entities like customers, products, and orders. This schema provides a tangible representation of how data would be structured in a relational database, highlighting primary and foreign keys that enforce data integrity and enable seamless data retrieval across different modules of the ERP system.Let’s consider a simplified schema for customer, product, and order management.The `Customers` table would store all customer-related information.

- `CustomerID` (INT, PRIMARY KEY, AUTO_INCREMENT): A unique identifier for each customer.

- `FirstName` (VARCHAR(50)): The customer’s first name.

- `LastName` (VARCHAR(50)): The customer’s last name.

- `Email` (VARCHAR(100), UNIQUE): The customer’s email address, which must be unique.

- `PhoneNumber` (VARCHAR(20)): The customer’s phone number.

- `AddressLine1` (VARCHAR(255)): The first line of the customer’s address.

- `City` (VARCHAR(50)): The city of the customer’s address.

- `StateProvince` (VARCHAR(50)): The state or province of the customer’s address.

- `PostalCode` (VARCHAR(20)): The postal code of the customer’s address.

- `Country` (VARCHAR(50)): The country of the customer’s address.

The `Products` table would contain details about the items offered for sale.

- `ProductID` (INT, PRIMARY KEY, AUTO_INCREMENT): A unique identifier for each product.

- `ProductName` (VARCHAR(100)): The name of the product.

- `Description` (TEXT): A detailed description of the product.

- `UnitPrice` (DECIMAL(10, 2)): The price of a single unit of the product.

- `StockQuantity` (INT): The current quantity of the product in stock.

The `Orders` table would record each sales order placed by a customer.

- `OrderID` (INT, PRIMARY KEY, AUTO_INCREMENT): A unique identifier for each order.

- `CustomerID` (INT, FOREIGN KEY REFERENCES Customers(CustomerID)): Links the order to a specific customer. This ensures that an order can only be associated with a valid, existing customer.

- `OrderDate` (DATETIME): The date and time the order was placed.

- `OrderStatus` (VARCHAR(50)): The current status of the order (e.g., ‘Pending’, ‘Processing’, ‘Shipped’, ‘Delivered’, ‘Cancelled’).

- `TotalAmount` (DECIMAL(10, 2)): The total value of the order, often calculated from order items.

The `OrderItems` table acts as a bridge between `Orders` and `Products`, detailing which products are included in which orders, and in what quantities. This is a classic example of resolving a many-to-many relationship.

- `OrderItemID` (INT, PRIMARY KEY, AUTO_INCREMENT): A unique identifier for each line item within an order.

- `OrderID` (INT, FOREIGN KEY REFERENCES Orders(OrderID)): Links this item to a specific order.

- `ProductID` (INT, FOREIGN KEY REFERENCES Products(ProductID)): Links this item to a specific product.

- `Quantity` (INT): The number of units of the product ordered in this line item.

- `LineItemPrice` (DECIMAL(10, 2)): The price for this specific line item (Quantity

– UnitPrice at the time of order).

This schema illustrates several key relationships:

- A customer can place multiple orders (one-to-many relationship between `Customers` and `Orders` via `CustomerID`).

- An order can consist of multiple products (many-to-many relationship between `Orders` and `Products`, implemented via the `OrderItems` junction table).

- Each entry in `OrderItems` links a specific order (`OrderID`) to a specific product (`ProductID`), and also records the quantity and the price at which it was sold.

This structure allows for efficient querying. For example, to find all orders placed by a specific customer, one would query the `Orders` table filtering by `CustomerID`. To see the details of products within a specific order, one would join `Orders` with `OrderItems` on `OrderID`, and then join `OrderItems` with `Products` on `ProductID`. This relational approach ensures data consistency and provides a flexible foundation for complex business logic within the ERP.

Illustrating the agile methodologies employed to iteratively build and refine enterprise resource planning software.

The development of complex enterprise resource planning (ERP) systems demands a flexible and adaptive approach to ensure alignment with evolving business needs and technological advancements. Agile methodologies provide precisely this framework, enabling teams to deliver value incrementally and respond effectively to change. Rather than a rigid, upfront design, agile focuses on collaboration, iterative development, and continuous feedback, making it an ideal choice for ERP projects that are often characterized by their scale and complexity.

This approach breaks down the monumental task of building an ERP into manageable chunks, allowing for regular review and adjustment.The core principle of agile in ERP development is to deliver working software frequently, allowing stakeholders to see tangible progress and provide input early and often. This iterative process mitigates the risk of building a system that doesn’t meet expectations by the time it’s completed, a common pitfall in traditional, waterfall development.

By embracing agile, organizations can foster a more dynamic and responsive development environment, leading to ERP solutions that are not only functional but also truly aligned with their strategic objectives and operational realities.

Benefits of Adopting Scrum or Kanban Frameworks for Managing Enterprise Resource Planning Development Sprints.

The adoption of agile frameworks like Scrum and Kanban offers substantial advantages when managing the development sprints of enterprise resource planning (ERP) software. These methodologies are designed to enhance collaboration, improve predictability, and accelerate the delivery of value, which are critical for large-scale projects like ERP implementations. Scrum, with its defined roles, events, and artifacts, provides a structured approach to iterative development.

For ERP projects, Scrum’s emphasis on fixed-length sprints (typically 1-4 weeks) ensures that development progresses in short, focused bursts. This allows teams to deliver potentially shippable increments of the ERP system at the end of each sprint. The daily stand-up meetings promote transparency and quick problem-solving, while sprint reviews offer a formal opportunity for stakeholders to inspect the increment and adapt the backlog.

The retrospective fosters continuous improvement within the development team. This structured cadence helps in managing the inherent complexity of ERP modules, ensuring that each component is developed and tested thoroughly before moving to the next. The predictability of sprint cycles allows for better resource allocation and project planning, crucial for managing the budget and timeline of an ERP initiative.Kanban, on the other hand, focuses on visualizing workflow, limiting work in progress (WIP), and managing flow.

For ERP development, Kanban can be particularly beneficial for teams that need more flexibility in their workflow or are dealing with a continuous stream of incoming requests or bug fixes. By visualizing the entire development process on a Kanban board, teams can identify bottlenecks and optimize the flow of work. Limiting WIP prevents teams from becoming overloaded and ensures that tasks are completed efficiently.

This can be invaluable for ERP projects where various modules or functionalities might have different development paces or dependencies. Kanban’s emphasis on continuous flow rather than fixed iterations can be advantageous for ongoing maintenance, enhancements, and the integration of new features into an existing ERP system. It allows for a more fluid response to changing priorities, which is common in dynamic business environments.

Both Scrum and Kanban, when applied thoughtfully to ERP development, lead to increased team efficiency, better product quality through frequent testing and feedback, and a higher degree of stakeholder satisfaction due to enhanced transparency and involvement. The ability to adapt to unforeseen challenges and incorporate user feedback throughout the development lifecycle is a hallmark of these agile approaches, making them indispensable for successful ERP system creation.

Practical Examples of User Stories and Backlog Prioritization within an Enterprise Resource Planning Development Context.

Effective user story creation and backlog prioritization are fundamental to the iterative success of enterprise resource planning (ERP) development. User stories capture requirements from the perspective of the end-user, focusing on the “who,” “what,” and “why” of a feature. In an ERP context, these stories are crucial for ensuring that the system addresses real business needs. For example, a user story for the inventory management module might be: “As an inventory manager, I want to be able to receive new stock against a purchase order so that my inventory levels are accurately updated in real-time.” This story is clear, concise, and describes a specific action and its benefit.

Another example, for the finance module: “As an accounts payable clerk, I want to automate the matching of invoices to received goods so that I can reduce manual data entry errors and speed up payment processing.” These stories translate complex business processes into actionable development tasks.Prioritization of the product backlog, which is a dynamic list of all features, enhancements, and fixes needed for the ERP system, is equally vital.

Techniques like MoSCoW (Must have, Should have, Could have, Won’t have) or value-based scoring are commonly employed. For an ERP project, ‘Must have’ features would include core functionalities like financial accounting, core HR processes, and basic inventory tracking, as these are essential for the system’s fundamental operation. ‘Should have’ features might involve advanced reporting capabilities, workflow automation for approvals, or integration with a specific third-party CRM.

‘Could have’ features are desirable but not critical, such as a mobile app interface for a specific user role or advanced analytics dashboards. ‘Won’t have’ defines features that are out of scope for the current release.Consider a scenario where a company is implementing a new ERP. The initial backlog might contain hundreds of user stories. The development team, along with product owners and key stakeholders, would collaborate to prioritize these.

For instance, the ability to process customer orders (a ‘Must have’ for sales operations) would be prioritized much higher than a feature for generating highly customized marketing brochures from customer data (potentially a ‘Could have’). The prioritization process often involves assessing business value, urgency, risk, and dependencies. If a particular module, like the manufacturing execution system (MES), is critical for the company’s core production, its associated user stories would be placed at the top of the backlog.

Conversely, features that support long-term strategic goals but don’t impact immediate operational needs might be placed further down. This continuous refinement and prioritization ensure that development efforts are always focused on delivering the most impactful functionality first, allowing for early realization of business benefits and a more controlled, iterative build of the comprehensive ERP solution.

How Continuous Integration and Continuous Delivery Pipelines Accelerate the Deployment of New Enterprise Resource Planning Features.

Continuous Integration (CI) and Continuous Delivery (CD) pipelines are instrumental in accelerating the deployment of new features within enterprise resource planning (ERP) system development by automating and streamlining the software release process. CI is a development practice where developers frequently merge their code changes into a central repository, after which automated builds and tests are run. For ERP systems, this means that as developers complete small pieces of functionality, such as a new field in a sales order form or a modification to a tax calculation, their code is automatically integrated with the main codebase.

This frequent integration helps in detecting and resolving integration issues early, preventing them from accumulating and becoming complex problems later in the development cycle. Automated unit tests and integration tests are triggered with every commit, ensuring that new code doesn’t break existing functionality. This constant validation provides a safety net, allowing developers to work with confidence and speed.Continuous Delivery, which builds upon CI, extends this automation to the entire release process, ensuring that code changes can be deployed to production at any time.

Once code has passed the CI stages, it is automatically prepared for release and deployed to various staging environments. This could include testing environments, user acceptance testing (UAT) environments, and finally, the production environment. The pipeline automates tasks such as code compilation, packaging, deployment to servers, and execution of more comprehensive end-to-end tests. For an ERP system, this means that a new module for expense management or an enhancement to the payroll processing can be developed, thoroughly tested, and made ready for deployment in a matter of hours or days, rather than weeks or months.The acceleration achieved through CI/CD pipelines is multifaceted.

Firstly, it significantly reduces the manual effort and human error associated with traditional release processes. Secondly, it provides rapid feedback loops to the development team, allowing them to quickly identify and fix defects. This iterative nature means that new ERP features are not delivered in large, infrequent batches, which are often risky and disruptive. Instead, smaller, more frequent releases become the norm, enabling businesses to adapt more quickly to market changes and user feedback.

For example, if a new regulatory requirement impacts financial reporting, a CI/CD pipeline allows the necessary adjustments to be made, tested, and deployed to production with unprecedented speed, minimizing compliance risks. Furthermore, the transparency provided by the pipeline, often visualized through dashboards, gives stakeholders clear visibility into the release status, fostering trust and enabling better planning. The automation inherent in CI/CD transforms the deployment of ERP features from a complex, high-risk operation into a predictable, efficient, and rapid process.

Understanding the crucial aspects of user interface and user experience design for enterprise resource planning applications.

In the realm of Enterprise Resource Planning (ERP) system development, the journey from raw data and intricate logic to a functional, business-enhancing tool culminates in how users interact with it. This is where User Interface (UI) and User Experience (UX) design take center stage. A powerful ERP system, no matter how robust its backend, will falter if it’s difficult to navigate, understand, or use efficiently.

Therefore, investing in thoughtful UI/UX design is not merely an aesthetic consideration; it’s a fundamental requirement for successful adoption, productivity, and ultimately, the realization of the ERP’s strategic business objectives. It transforms a complex technological solution into an accessible and empowering instrument for every employee.The success of any ERP system hinges on its ability to be readily adopted and effectively utilized by its intended audience.

This is where a deep understanding of UI and UX principles becomes paramount. An intuitive interface ensures that users can find what they need quickly and perform their tasks with minimal friction, thereby reducing the learning curve and increasing overall efficiency. Conversely, a poorly designed UI can lead to frustration, errors, and a reluctance to use the system, negating its potential benefits.

Therefore, a user-centric approach throughout the development lifecycle is essential, focusing on how individuals will interact with the system to achieve their daily objectives.

Intuitive Navigation and Clear Information Hierarchy in Enterprise Resource Planning Interfaces

The effectiveness of an ERP system is profoundly impacted by how easily users can move through its various modules and access the information they require. This necessitates a meticulously planned navigation structure and a logical arrangement of data. Without intuitive navigation, users can become lost, spending valuable time searching for functionalities or data points, which directly translates to decreased productivity and increased operational costs.

A clear information hierarchy, on the other hand, ensures that critical data is presented prominently and that related information is grouped logically, allowing users to grasp complex datasets at a glance and make informed decisions swiftly. This structured approach minimizes cognitive load, making the system feel less overwhelming and more manageable, even for users with limited technical expertise.Consider the contrast between two ERP interfaces: one with a sprawling, unorganized menu structure and another with a well-defined, categorized navigation bar and breadcrumbs.

In the former, a sales representative might struggle to locate the customer order history, potentially clicking through multiple irrelevant screens. In the latter, the same task would involve a straightforward click on “Sales” followed by “Orders” and then “Customer Search,” with clear indicators of their current location within the system. This clarity extends to how information is presented on screens.

For instance, a financial report should not just be a wall of numbers; it should feature clear headings, logical data groupings (e.g., by department, by fiscal period), and visual aids like charts or graphs to highlight key trends and outliers. This organized presentation allows users to quickly identify critical metrics, understand performance, and pinpoint areas requiring attention without needing to sift through excessive detail.

“The ultimate goal of intuitive navigation and clear information hierarchy is to make the ERP system disappear into the background, allowing users to focus on their tasks, not on how to operate the software.”

When designing these elements, several factors come into play. The principle of “less is more” is often applicable; avoiding cluttered screens and overwhelming users with too many options at once is crucial. Consistent placement of navigation elements across all modules ensures predictability, reducing the need for users to re-learn navigation patterns as they move between different functional areas. Furthermore, the use of clear and concise labeling for menu items, buttons, and data fields is vital.

Ambiguous terms can lead to misinterpretations and errors. For example, a button labeled “Process” might have different meanings in different contexts, whereas “Submit Invoice” or “Approve Purchase Order” leaves little room for doubt. Ultimately, a well-executed navigation and information hierarchy transforms a potentially daunting ERP system into a streamlined and efficient tool that actively supports business operations.

Design Considerations for Creating Role-Based Dashboards that Cater to the Specific Needs of Different User Groups

In an enterprise setting, users interact with an ERP system from vastly different perspectives and with distinct objectives. A sales manager needs to monitor pipeline, track team performance, and forecast revenue, while an inventory clerk requires real-time stock levels, order fulfillment status, and reorder alerts. A human resources professional will be focused on employee data, payroll, and recruitment metrics. Acknowledging these diverse needs is the foundation for designing effective role-based dashboards.

These dashboards are not generic landing pages; they are curated views of critical information tailored to the specific responsibilities and decision-making requirements of individual user roles or groups. This personalization significantly enhances efficiency by presenting the most relevant data upfront, reducing the need for users to navigate through irrelevant modules or reports.The design process for role-based dashboards begins with a thorough understanding of each user group’s daily tasks, key performance indicators (KPIs), and common pain points.

For instance, a procurement officer’s dashboard might prominently display pending purchase orders, supplier performance ratings, and budget utilization reports. Conversely, a customer service representative’s dashboard would likely feature open support tickets, customer history summaries, and service level agreement (SLA) status. The goal is to provide a snapshot that enables immediate action and informed decision-making without requiring the user to dig for information.

This involves carefully selecting which data points to display, how frequently they should be updated, and in what visual format they will be most impactful.

“Role-based dashboards transform raw ERP data into actionable intelligence, empowering users to perform their duties with greater speed and accuracy.”

Key design considerations include:

- Data Visualization: Employing appropriate charts, graphs, and tables to represent data in an easily digestible format. For example, a line graph might be ideal for showing sales trends over time, while a bar chart could effectively compare departmental budget spending.

- Key Performance Indicators (KPIs): Highlighting the most crucial metrics that directly reflect the user’s success and the organization’s goals. These KPIs should be clearly labeled and, where possible, include trend indicators (e.g., an arrow showing an upward or downward movement compared to the previous period).

- Actionable Insights: Designing dashboards that not only present data but also suggest or facilitate immediate actions. This could include buttons to quickly approve a request, generate a report, or escalate an issue.

- Customization Options: Allowing users some degree of personalization within their role-based dashboard, such as the ability to reorder widgets or select specific date ranges, can further enhance usability and ownership.

- Real-time Updates: Ensuring that critical data is refreshed frequently enough to be relevant for decision-making, especially for roles that require immediate operational awareness.

By meticulously considering these aspects, organizations can create ERP dashboards that are not just visually appealing but are powerful tools that drive efficiency, improve decision-making, and foster a more engaged user base.

Methods for Incorporating User Feedback Loops to Iteratively Improve the Usability of Enterprise Resource Planning Software

The development of an ERP system is not a one-time event but an ongoing process of refinement, especially when it comes to its usability. User feedback loops are indispensable mechanisms for gathering insights directly from those who interact with the system daily, allowing for continuous improvement and adaptation. Without these loops, even the most meticulously designed ERP can become outdated or fail to address evolving user needs and business processes, leading to decreased adoption rates and a diminished return on investment.

By actively seeking, analyzing, and acting upon user feedback, development teams can ensure the ERP remains a relevant, efficient, and user-friendly tool throughout its lifecycle.Several effective methods can be employed to establish robust user feedback loops:

- In-App Feedback Mechanisms: Integrating simple, non-intrusive feedback tools directly within the ERP interface. This could include “rate this feature” buttons, short surveys triggered after specific actions, or a dedicated “report an issue” or “suggest an improvement” option accessible from any screen. These methods capture feedback in the context of the user’s experience, making it highly relevant. For example, after a user completes a complex data entry task, a prompt might appear asking, “How easy was this process on a scale of 1 to 5?” followed by an optional text field for comments.

- Usability Testing Sessions: Conducting structured usability testing with representative users from different departments. These sessions involve observing users as they attempt to complete predefined tasks within the ERP system. Think-aloud protocols, where users verbalize their thoughts and actions, are particularly valuable for uncovering usability issues and understanding user thought processes. For instance, a test might involve asking a finance user to generate a quarterly P&L statement, observing where they struggle, what questions they ask, and how long it takes.

- User Advisory Boards or Focus Groups: Establishing regular meetings with a select group of power users or representatives from key departments. These groups can provide in-depth feedback on new features, discuss ongoing challenges, and help prioritize development efforts. These sessions are more strategic and allow for deeper dives into specific functionalities or upcoming changes. A focus group might discuss the proposed redesign of a reporting module, offering insights into its potential impact on their workflows.

- Surveys and Questionnaires: Distributing targeted surveys to gather feedback on specific aspects of the ERP system or to gauge overall user satisfaction. These can be conducted periodically, for example, annually, or in response to significant updates. A comprehensive survey might cover aspects like navigation, performance, feature usefulness, and training effectiveness.

- Support Ticket Analysis: Regularly reviewing support tickets submitted by users. The patterns and recurring issues identified in support logs often highlight areas of the ERP system that are confusing, buggy, or inefficient. Analyzing these tickets can reveal common user pain points that might not surface in more direct feedback methods. For instance, a high volume of tickets related to password resets or data import errors indicates a need for clearer instructions or more robust error handling.

The crucial element in any feedback loop is the action taken based on the insights gained. This involves a process of analyzing the feedback, prioritizing issues based on impact and frequency, and then integrating the necessary changes into the ERP development roadmap. Communicating back to users about the changes made based on their feedback is also vital, fostering a sense of partnership and encouraging continued engagement.

This iterative cycle of feedback, analysis, and improvement ensures the ERP system remains a powerful and user-friendly asset for the business.

Addressing the multifaceted challenges inherent in migrating existing business data into a newly developed enterprise resource planning system.

Migrating existing business data into a new ERP system is a critical, yet often complex, phase of any implementation. It’s the bridge that connects the legacy operational landscape to the modernized, integrated future. This process involves moving vast amounts of information, from customer records and financial transactions to inventory levels and employee details, ensuring accuracy, completeness, and accessibility in the new environment.

Without a well-orchestrated migration strategy, the benefits of a new ERP can be severely undermined, leading to operational disruptions, data integrity issues, and user distrust.The transition from disparate, often siloed, legacy systems to a unified ERP platform necessitates meticulous planning and execution. This phase is not merely a technical transfer of data; it’s a strategic undertaking that impacts every facet of the business.

The potential for errors is significant, and the consequences of a failed migration can be far-reaching, including extended downtime, financial losses, compliance breaches, and a substantial hit to user adoption and overall project success. Therefore, understanding and proactively addressing the inherent challenges are paramount.

Common Pitfalls in ERP Data Migration Projects

The journey of migrating data into a new enterprise resource planning system is fraught with potential obstacles that, if not anticipated and managed, can derail the entire project. These pitfalls often stem from a lack of thorough preparation, underestimation of complexity, or insufficient resources allocated to this crucial stage. Understanding these common traps is the first step toward avoiding them and ensuring a smoother, more successful transition.One of the most prevalent issues is the underestimation of data volume and complexity.

Businesses often possess a historical accumulation of data that is far larger and more intricate than initially perceived. This can include historical transactional data, numerous custom fields, and legacy data formats that are difficult to interpret or reconcile. Another significant pitfall is poor data quality. Existing systems may contain duplicate records, incomplete entries, outdated information, or inconsistent formatting, all of which can contaminate the new ERP system if not addressed.

This “garbage in, garbage out” scenario can severely hamper the effectiveness of the new system.Furthermore, lack of clear data ownership and accountability often leads to confusion and delays. Without designated individuals responsible for specific data sets, decisions regarding data cleansing, mapping, and validation can stall. Inadequate testing and validation are also critical failures. Migrating data without rigorous testing cycles to verify accuracy, completeness, and business rule adherence can result in critical errors going unnoticed until they impact live operations.

This can lead to significant financial discrepancies, incorrect reporting, and operational chaos.Another common mistake is insufficient stakeholder involvement. Data migration impacts various departments, and failing to involve key users and department heads in the process can lead to misinterpretations of data requirements and business logic. Finally, underestimating the time and resources required for data migration is a recurring problem. It’s often viewed as a secondary task to system implementation, when in reality, it demands dedicated teams, specialized tools, and significant time investment.

The sheer effort involved in extracting, transforming, and loading data, coupled with the necessary validation steps, is frequently underestimated. For instance, a retail company might underestimate the complexity of migrating millions of individual sales transactions, each with multiple line items and associated customer and product data, across years of operation.

Understand how the union of enterprise resource planning can improve efficiency and productivity.

Essential Steps in Data Cleansing, Transformation, and Validation

Before any data can be safely and effectively loaded into a new enterprise resource planning system, a rigorous process of cleansing, transformation, and validation must be undertaken. This meticulous preparation ensures that the data entering the new system is accurate, consistent, and ready to support business operations. Skipping or rushing these steps is a recipe for disaster, leading to the perpetuation of old errors in a new, integrated environment.The initial phase, data cleansing, involves identifying and rectifying inaccuracies, inconsistencies, and incompleteness within the source data.

This can include removing duplicate records, correcting spelling errors, standardizing formats (e.g., dates, addresses, phone numbers), and filling in missing essential fields. For example, a customer database might have multiple entries for the same individual due to variations in name spelling or address, which need to be consolidated into a single, accurate record. Tools can assist in identifying patterns for deduplication, but human oversight is often necessary for complex cases.Following cleansing, data transformation comes into play.

This step involves converting the cleansed data from its original format into a format that is compatible with the new ERP system’s data structures and requirements. This might involve reformatting fields, mapping legacy codes to new ERP codes, or aggregating data to fit the target system’s schema. For instance, a legacy inventory system might use a three-digit product code, while the new ERP requires a ten-digit alphanumeric code.

The transformation process will convert these codes accurately. This also includes handling different data types, such as converting text fields to numerical values or vice versa, and ensuring that data relationships are maintained.The final, crucial step is data validation. This is the process of verifying that the cleansed and transformed data is accurate, complete, and conforms to all business rules and integrity constraints of the new ERP system.

Validation occurs at multiple levels: first, checking individual data records for accuracy and completeness; second, verifying relationships between different data sets (e.g., ensuring that every sales order is linked to a valid customer and product); and third, performing business-rule validation to confirm that the data adheres to operational logic (e.g., ensuring that discount percentages are within acceptable limits). A comprehensive validation strategy often involves reconciliation reports, comparing counts and sums between source and target systems, and conducting user acceptance testing with sample data sets.

Strategies for Minimizing Downtime and Ensuring Data Integrity